Cold extrusion fasaha na karfe mashaya hannun riga

Halayen sanyi extrusion fasaha na karfe bar hannun riga

(1) The yi fasaha na sanyi extrusion dangane da karfe mashaya hannun riga ne mai sauki da kuma sauki Master.

(2) The karfe mashaya hannun riga sanyi extrusion dangane fasaha iya ajiye lokaci mai yawa a yi idan aka kwatanta da gargajiya waldi hanya.

(3) Idan aka kwatanta da na gargajiya karfe bar walda dangane gina, sanyi extrusion dangane fasaha na karfe mashaya hannun riga iya rage aikin kudin.

(4) Cold extrusion dangane fasaha na karfe mashaya hannun riga ya dace da radial extrusion dangane da ribbed karfe mashaya da diamita φ16-φ40 a karfafa kankare tsarin.

Fasaha da bukatun ga sanyi extrusion na karfe mashaya hannun riga

Dole ne a yi amfani da fasahar extrusion da ta dace da ma'aunin karɓuwa mai ma'ana a cikin ginin haɗin shingen ƙarfe na ƙarfe don tabbatar da ingancin ginin ya cika ƙa'idodin ƙira.

Materials da kayan aiki don sanyi extrusion dangane da karfe mashaya hannun riga

(1) Kayayyaki

1, karfe

Ƙarfe da aka fitar dole ne ya kasance yana da takardar shedar inganci, kuma siffarsa, girmansa da kayan aikin injiniya ya kamata ya dace da bukatun ƙasa.Dole ne a bincika rebar kafin amfani kuma a ɗauki samfurori don gwajin kaddarorin inji.Hakanan ya kamata a gudanar da nazarin abubuwan da ke tattare da sinadarai lokacin da gaggauce karaya da kaddarorin injina na ƙarfafawa ba su da kyau a fili.Lokacin da aka adana rebar kuma an ɗauke shi, alamar saman ba za ta lalace ba, kuma za a jera shi da kyau daidai gwargwado don guje wa lalata da gurɓatawa.

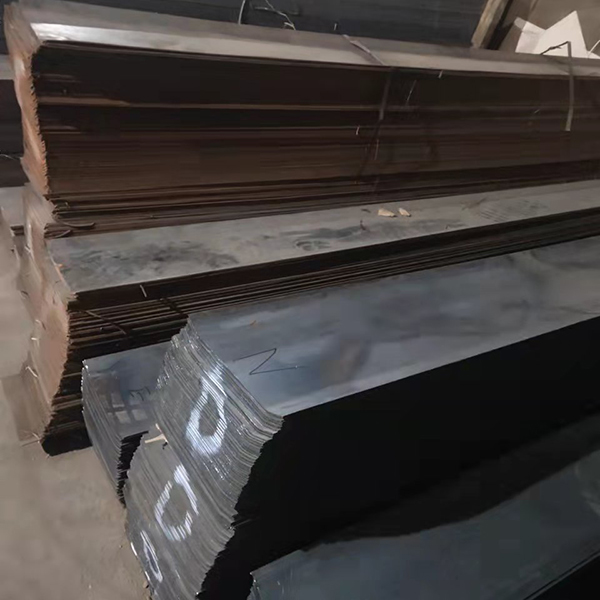

2, hannu

Kayan hannun riga an yi shi da bututun ƙarfe mara nauyi wanda ya dace da calending.Abubuwan da aka auna na inji, girman hannun riga da sabawa sun dace da buƙatun.Za a kiyaye hannayen riga daga lalacewa da gurɓatacce yayin ajiya da sufuri, kuma za a bincika kuma a karɓa cikin batches yayin karɓa.Za a tara hannayen riga bisa ga ƙayyadaddun bayanai daban-daban yayin ajiya, kuma hannayen riga za su sami takardar shaidar masana'anta.

(2) Kayan aiki

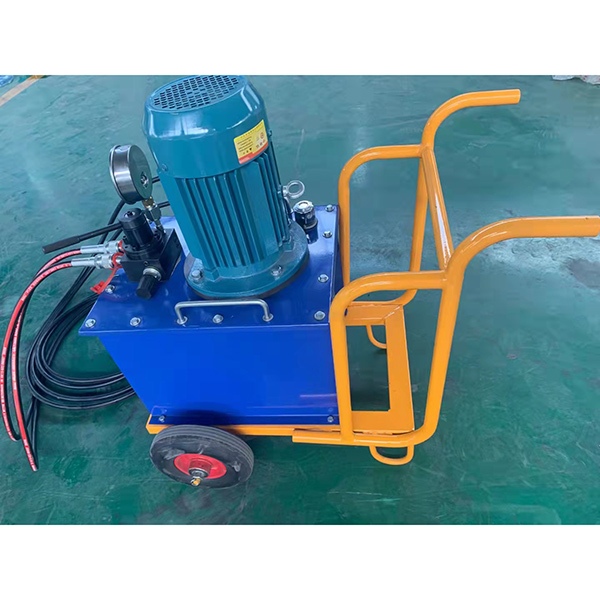

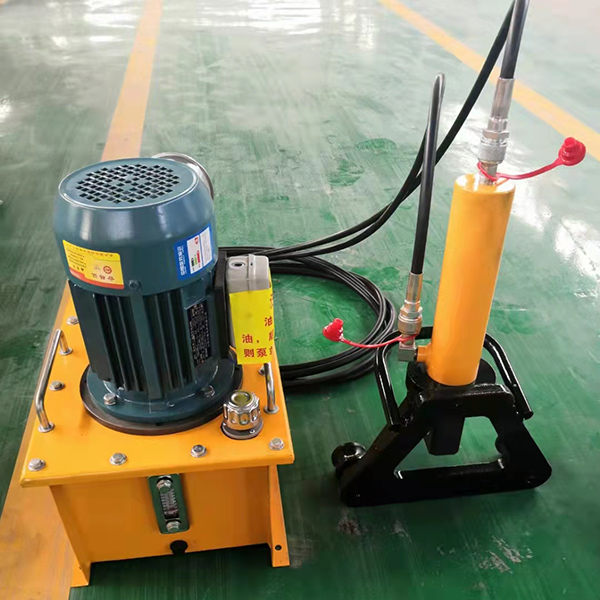

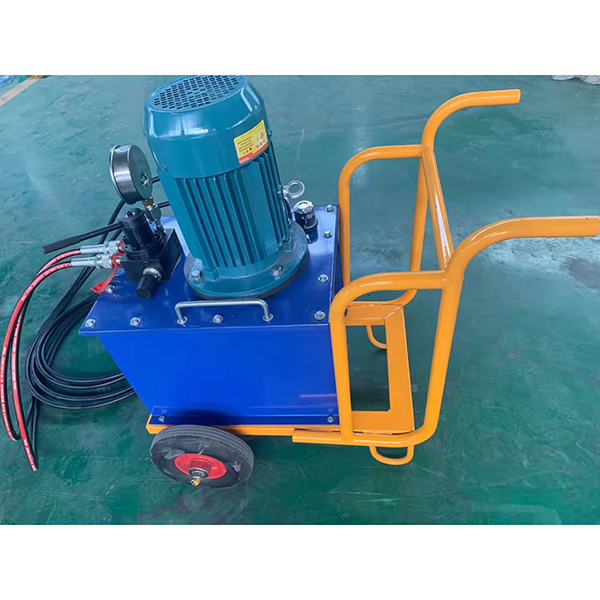

1, kayan aikin extrusion

Extrusion haɗa kayan aiki sun hada da crimper, matsananci-high matsa lamba man famfo da matsananci-high matsa lamba mai bututu.Ultra-high matsa lamba mai famfo ne ikon tushen extrusion, rated aiki matsa lamba ne 80Mpa;Na'urar crimping shine sassan zartarwa na extrusion karfe, akwai samfura biyu, matsakaicin matsa lamba na 100Mpa;Yjh-32 ya dace da crimping φ16-φ32 karfe sanduna, yJH-40T ya dace da crimping φ32-φ40 karfe sanduna.Latsa mutu, hannun riga, karfe ya kamata a yi amfani da shi tare, akwai ƙayyadaddun ƙayyadaddun latsa mutun guda tara, lambar da aka yiwa alama akan mutun tana wakiltar diamita na sandar ƙarfe, yakamata a bincika lokacin amfani.

The karfe bar hannun riga sanyi extrusion haɗa kayan aiki kuma ya hada da extrusion karin kayan aiki da extrusion na musamman kayan aiki.Extrusion karin kayan aiki: shimfidawa, angular grinder, da dai sauransu;Extrusion kayan aiki na musamman ya haɗa da: katin alamar, allon katin girman.

Uku, gina haɗin sanyi extrusion na ƙarfafa hanyar bututu

Cold extrusion dangane gina tsarin aiki

1. Bincika ko kayan aikin extrusion yana gudana akai-akai kafin aikin haɗin haɗin gwiwa na sanyi na sandar karfe, da daidaita matsa lamba don saduwa da buƙatun kafin aikin.

2. Karfe hannun riga da mold aka zaba bisa ga ƙayyadaddun na haɗa karfe mashaya.Samfuran ƙira don haɗa sandunan ƙarfe tare da diamita iri ɗaya da ƙirar ƙira don haɗa sandunan ƙarfe tare da rage diamita ya kamata su bi abubuwan da suka dace a cikin JGJ107 da JGJ108 bi da bi.

3. Cire tsatsa, yashi, mai da sauran abubuwan da suka dace daga sassan da aka haɗa na sandar karfe.

4. Gwada sandar karfe da hannun karfe.Idan ƙarshen sandunan ƙarfe yana da babban takalmin dawaki, lanƙwasa ko girman girman hakarkarin tsayi, ya kamata a gyara shi a gaba ko kuma a goge shi da dabaran niƙa, amma an hana shi goge haƙarƙarin maƙarƙashiya na sandar ƙarfe da yanke sashin da ya wuce girman ta hanyar walda ta lantarki.

5, tare da zurfin mai mulki a cikin sandar karfe ƙarshen fenti matsayi alamar, an saka alamar sakawa a cikin tsayin hannun hannu na ƙarfe, duba nisan alamar daga alamar sakawa 15mm, don bincika ko an saka sandar ƙarfe a wurin bayan crimping.

6. Saka sandar karfe a cikin hannun karfe bisa ga alamar matsayi.Ƙarshen sandar ƙarfe bai kamata ya zama fiye da 5mm daga tsakiyar tsakiyar tsawon hannun riga ba.

7, bisa ga tanadin lokutan latsawa da shigar da latsawa.

Nuni samfurin